Author: divingdiynut

Monday 16th August External demo in our normal meeting room, restricted to 24 members due to school covid rules.

The nights audience

Tony Jones was the external demonstrator from the local Bescot wood turning club he also teaches wood turning.

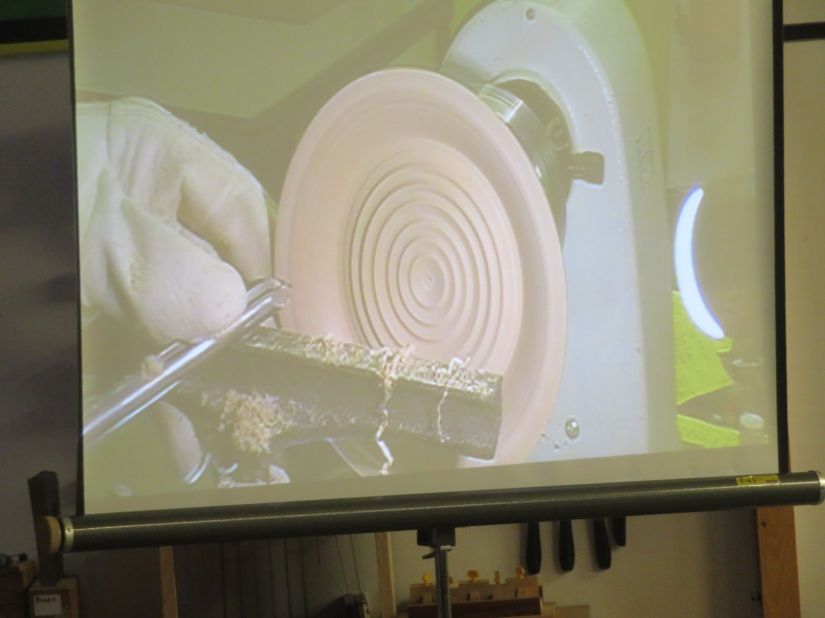

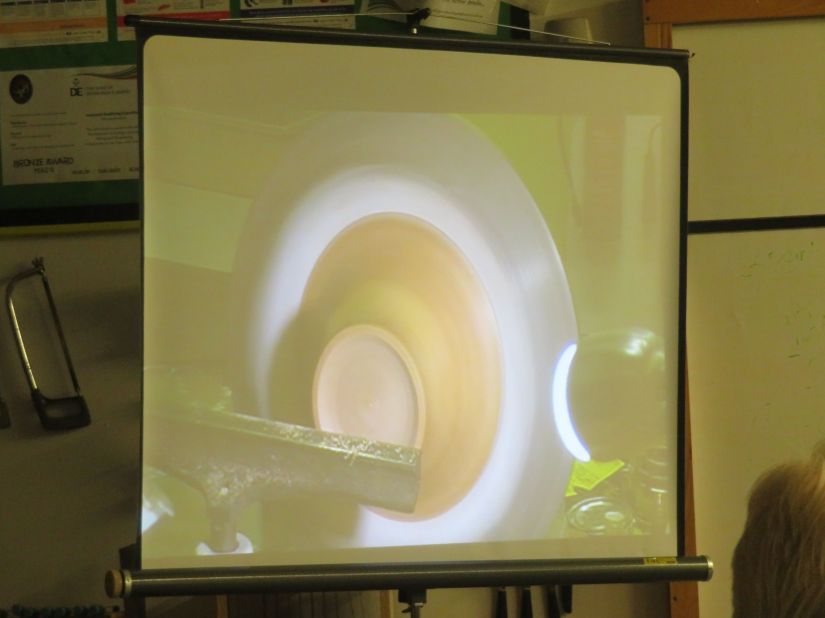

He demonstrated one of his signature pieces a thin walled Vortex Bowl

Tony demonstrated the safe use of the lathe, correct presentation of the turning tools and a way to restrict sanding dust using a paste wax whilst applying abrasives.

The reasons for choosing the holding mechanism & his method of producing a 1.5 mm thick walled vessel.

In all an enjoyable evening for all present, some new knowledge gained by most members

who showed their appreciation to Tony at the end.

Monday August 2nd first Post Covid Meeting.

A catch up meeting held in the schools dinning hall to allow the full membership to attend as due to covid restrictions still being required by the school our normal meeting room is limited to an attendance of only 24.

Barry the chairman went through a number of concerns and problems the committee & club still have to face whilst trying to get the club back to a normal meeting format & programme.

Some of the content will have to be repeated at the A.G.M. as only 23 members managed to attend.

It is important that members attend to fully appreciate what restrictions & concerns the committee has been having to deal with.

A lighter note However was the response to the chairmans two challenges.

The car build & race a £10 prize was won for best design chosen by a club member Winner the domino .

and £10 for the furthest travel launched down a ramp the winner shown below.

2nd challenge a pagoda house roof build supplied by 3 members.

Barry & other attendees.

Monday march 2nd Pro Demo by Richard Findley

On the 2nd March 38 members welcomed Richard Findley the accomplished demonstrator and professional jobbing wood turner.

Richard’s chosen project for the night was his take on a “picture-Frame insert box” by Chris Stott. Richards box was walnut with a pewter insert.

Richard started by melting and pouring a pewter insert into a dry wooden mould. The insert incorporated a 18 mm diameter sprue which he used to hold the insert whilst turning and finishing after sufficient cooling had taken place. The highly polished finish was achieved by working thru the various sanding grits and a final polish with brasso (but “T” cut would do the same job).

Whilst turning the box Richard demonstrated hollowing end grain using a spindle gouge, and how to achieve a closefitting lid by making the male spigot very slightly domed,

and using a lot of patience. A Ray Key inspired lip defined the join between lid and base. The audience was also shown how to make, use and sharpen a negative rake scraper which was used to refine the finish inside the box.

Richard kindly donated the box to our charity.

An extremely entertaining, informative and well-presented demonstration warmly applauded by the club members.

Find more about Richard at https://turnersworkshop.co.uk

Monday 16th March Project & Gallery

With Droitwich school still open for pupils and no staff or pupils currently in self isolation, we held our project and gallery evening all beit with a limited number of members due to Covid-19. Members were invited to make “something reverse turned(inside out) or off centre turned”. You will see from the photo’s that there were a good number of items entered. Each member presenting their contributions.

The gallery again was well represented with items ranging from segmented to spiral to router-cut examples.

During the evening there were quite a few questions and answer, when the attendees had the opportunity to ask advice & give advice on a number of aspects eg How to mark out and hollow spiral projects, pitfall’s to avoid in segmentation, and how to remove/avoid shadow marks from carnuba wax polishing. Along with the odd failure (learning by mistakes)