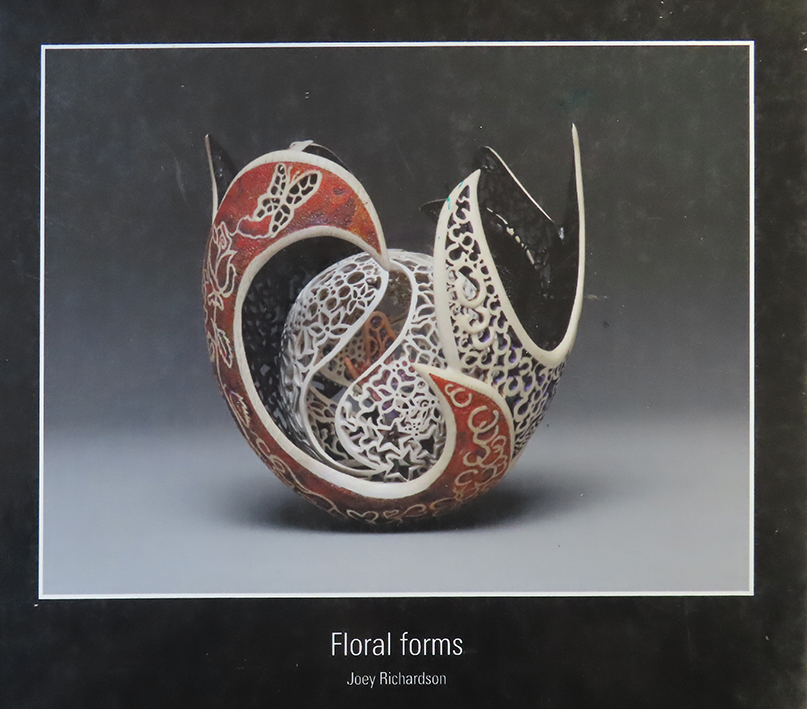

All Day Demo by Joey Richardson

This year’s all day demonstration was given to the club by internationally acclaimed wood artist and current President of the AWGB Joey Richardson. Her delicate and highly individual works are sought by collectors all over the world and so it was a privilege to see how she goes about creating her pieces.

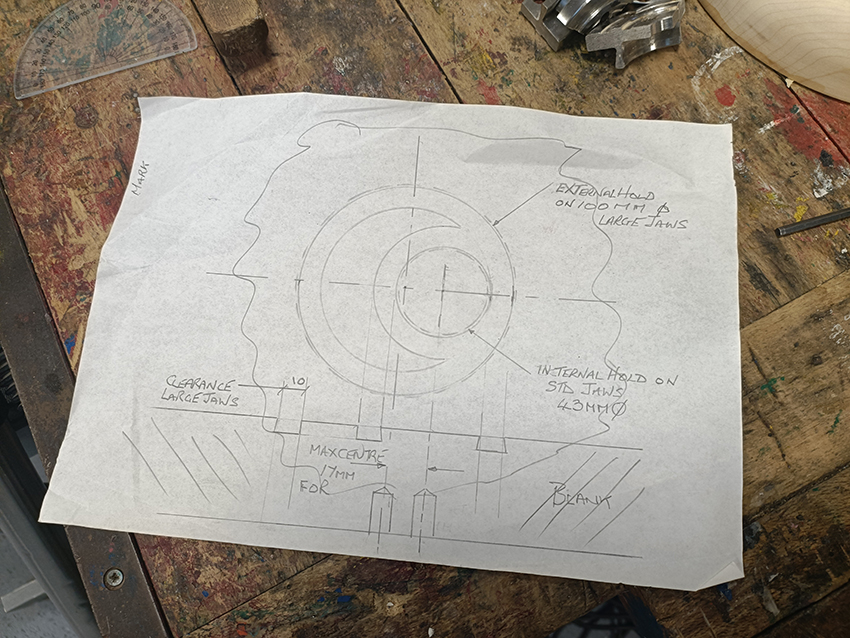

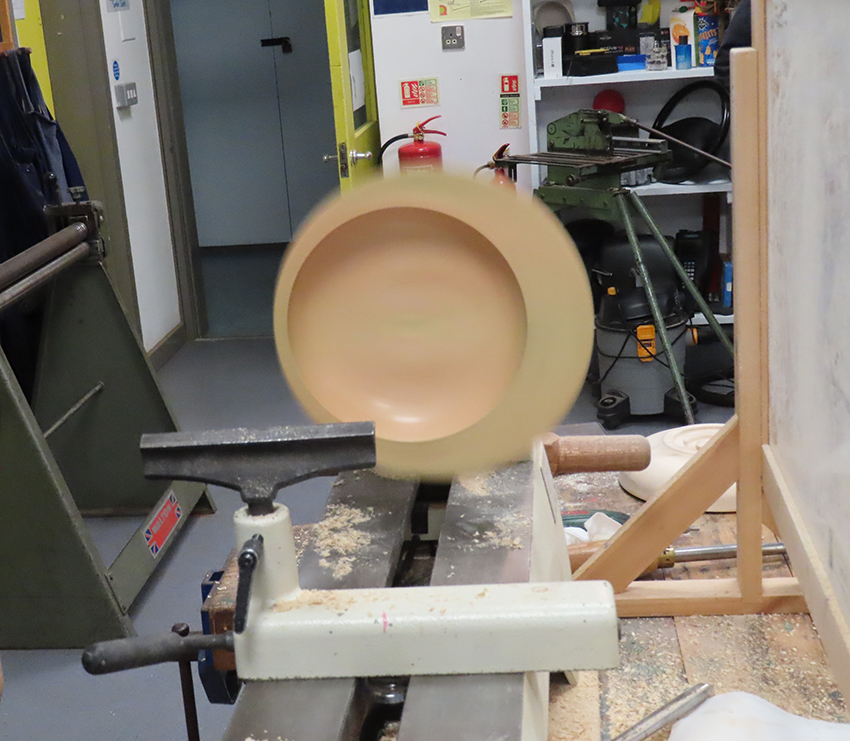

She split the day into 3 sections – woodturning, carving and piercing and finally decorating. Firstly she turned and hollowed a piece of green sycamore (her preferred wood) using only a bowl gouge and carbide cutter. Lamps were used inside and outside the wood to achieve the thin walls that she needed.

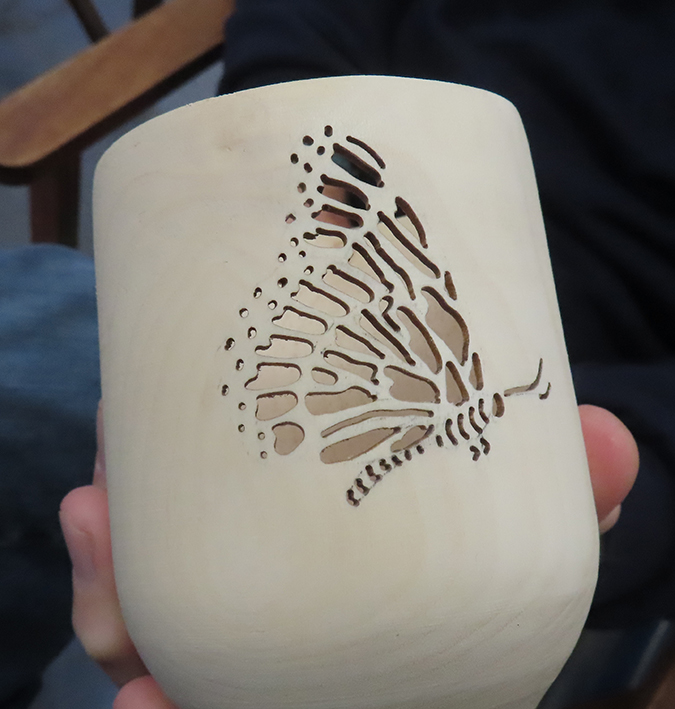

This done she showed how to then transfer a design onto the outside of the vessel prior to piercing and carving. Several machines were used for this and Joey discussed the relative merits of each while, all the time, telling us about her own woodturning and artistic journey.

After lunch we moved onto, what I suspect, is Joey’s favourite part of her work – the decoration. We were taken through a magical mystery tour of stencil making, masking, pyrography and airbrushing in layers which she applied to a number of examples.

A fantastic and informative day from someone with a unique perspective on the art and craft of woodturning. Hopefully an inspiration to us all.